CNC lathe boring bar is on of the CNC turning machine center tool used to enlarge the inner diameter of the pre-existing hole on the rotationally-symmetrical workpiece or cylindrical workpiece. CNC lathe boring bar consists of a long bar and an insert or a single-point cutting tool which will be positioned at the end of the long bar and use in the boring operations. Boring bar is needed especially to get an accuarate large diameter and high surface roughness in the inner surface of the cylindrical workpiece.

Boring bar

Insert or single-point cutting tool attached on the long bar and the combination of both known as boring bar

Boring operation using boring bar tool performed on the CNC turning machine center

Before the boring bar can be used in the boring operation on the cylindrical workpiece, a small hole need to drill on the center diameter of the workpice and the hole diameter must be sufficient enough to accommodate the boring bar or the boring tool. For high surface roughness, I myself use roughing cut, boring tool feed rate range from 2 to 4 feed per minute, spindle speed equal to 180 RPM and depth of cut equal to 2.5 mm. For finishing, the boring tool feed rate equal to 5 or 6 feed per minute, spindle speed is 400 RPM and depth of cut is 0.5 mm. The workpiece material is mild steel SS41

Summary for boring bar cutting operation:

Boring Bar Roughing Cut

Feed Rate = 2 ~ 4 F/M (Feed Per Minute)

Spindle Speed = 180 RPM ( Rotation Per Minute)

Depth of Cut = 2.5 mm (millimeter)

Boring Bar Finishing Cut

Feed Rate = 5 ~ 6 F/M

Spindle Speed = 400 RPM

Depth of Cut = 0.5 mm

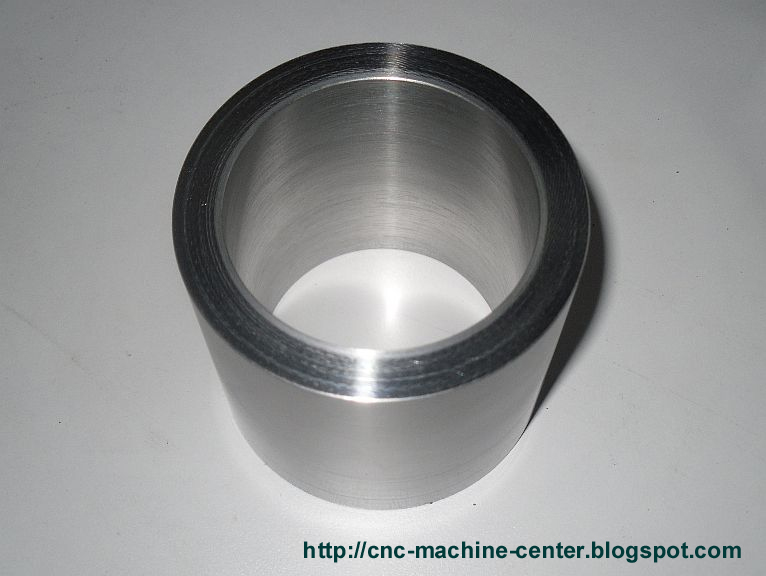

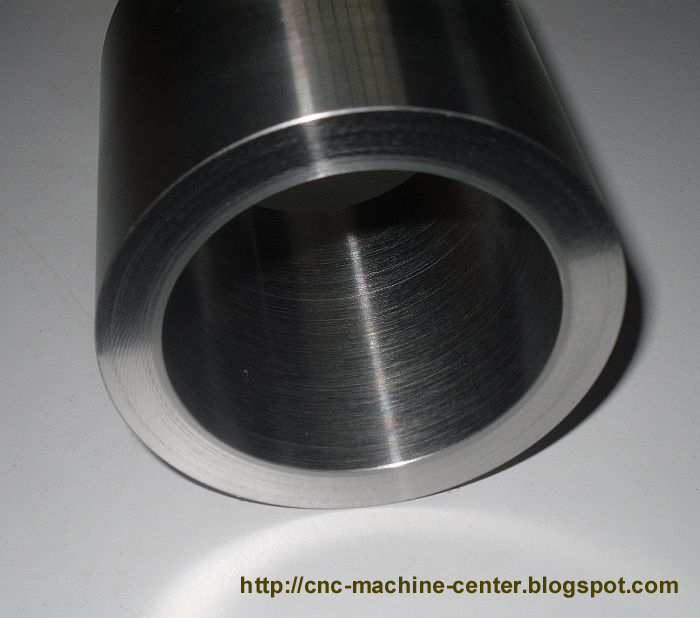

Completed machining part. Other machining methods involved to complete this part are turning, facing and drilling

Cylindrical workpiece mild steel SS41 with high surface roughness

Toyota HID Kit

-

By Najeeb Ullah

This articles is about the HID kits of Toyota and its installation

It is true that most of the drivers are not happy with their stock Toyot...

2 Comments:

thank's of explain detail cnc lathe machines

your blog is very nice... i would like introduce my blog which provides latest information regarding cnc machine

Post a Comment