What is Waterjet Cutting Machine? A Waterjet Cutting Machine is a machine tool uses a specific and a consistent high pressure pressurized water called waterjet which supplied by high pressure pump to cut or pierce variety of metal or non-metal materials.

CNC Waterjet Cutting Machine is consistently deliver an extremely high level of cutting precision, accuracy and performance that fully utilize the waterjet cutting technology which uses CNC G codes and CNC M codes to control the overall machie cutting process.

There are two type of waterjets used by Waterjet Cutting Machines to cut materials. There are Pure Waterjet and Abrasive Waterjet. A Waterjet Cutting Machine might used pure waterjet or abrasive waterjet or both method to cut almost any materials. Pure waterjet uses to cut a variety of soft materials such as paper, rubber, foam and baby diapers. The abrasive waterjet uses to cut almost any hard materials such as titanium, stainless steel, stone and glass.

How a Waterjet Cutting Machine Works?

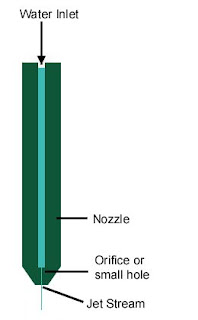

How Waterjet Cutter works? Basically, the Waterjet Cutter or Waterjet Cutting Machine uses the technology of high pressurized water supplied by high pressure pump and delivers it consistently and continuously up to 90,000 psi or 6200 Bar (620 MPa) and forced it through a pre-mounted orifice or small hole as small as 0.005 inches (0.127 mm), it will create a jet stream called pure waterjet.

Pure Waterjet

If a small amount of abrasive material such as granet is mixed into the jet stream, it will create a jet stream called abrasivejet or abrasive waterjet. The jet stream flow exits the nozzle will make contact with the surface of workpiece. The workpiece will develop small cracks due to jet stream impact and propagate until the material is cut through.

Abrasive Waterjet

CNC Waterjet Cutting Machine - JETMax HS 4020

Photo by Maximator JET GmbH

3 Comments:

Are the informaton here more of the technology side? How about shops performing these machining practice, do you have any reference?

I am interested in shops doing gearbox modification like adding Power Take-off (PTO) to a basic sets of gear drive.

Thank you,

ZyberDon

http://juneayasol.ipower.com/flyingcar

Since, its development, water jet machining has seen many improvements in its design. Many different types of abrasives, nozzles, flow rates, and jet positions have been experimented with, to name a few.

----

water jet cutting service

Such an interesting and informative blog to read. Thank you for sharing this blog.

CNC Machines

Post a Comment